MSRP: $11,054.77 PER UNIT

Get Megatron Tank Specifications & Installation Manual pdfs by clicking the download buttons.

Or, use the accordions and tabs below to read about features and specifications without leaving this page.

MEGATRON TANK

SUPER HEAVY DUTY

High-traffic Commercial

Megatron Tank Mechanical Specifications

Specifications listed in blue are unique to to Megatron Tank

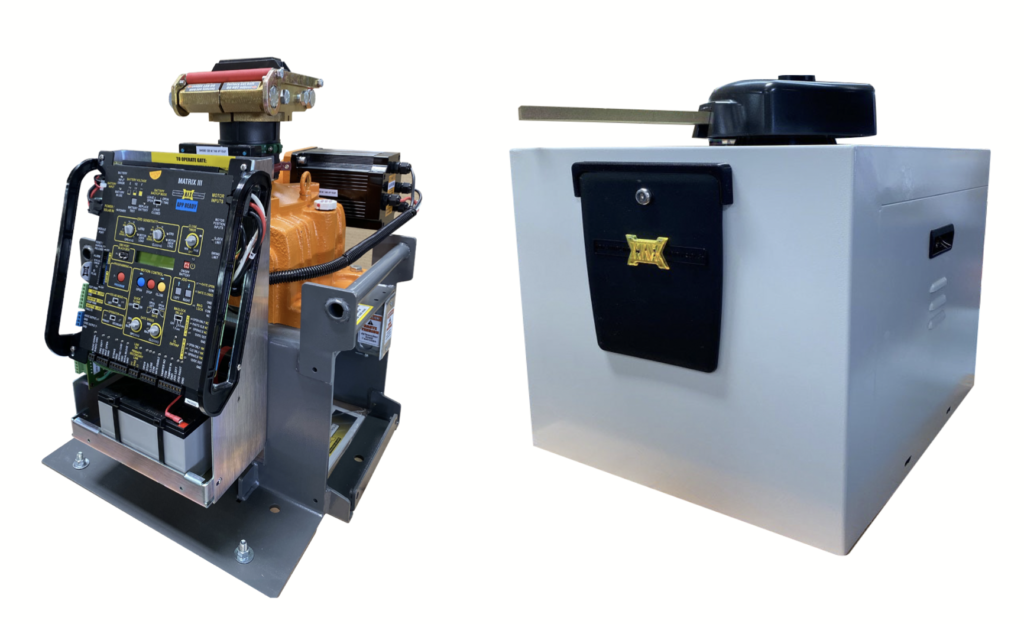

- Max Megatron Tank dimensions (19.25 W x 23 D x 25 H) 22.5 arm height

- Heavy duty dual gear box 900:1 Size 100 for Megatron Tank – 120 lbs.

- Megatron Tank capacity 4500lbs /10ft or 3000lbs/30ft

- Large output shaft: 31⁄4” diameter solid steel with cast iron clamping system for all Megatron

- Direct gear drive (no chains, belts, or pulleys)

- Mechanical and electrical manual gate release functions

- Corrosion protection gold zinc coating and powder coating

- Continuous cycle at extreme temperature range; no overheating possibilities

- Intelligent ramp-up and ramp-down gate speed control for smooth operation

- Shipping weight of Max Megatron Tank (323 lbs)

Megatron Tank Electrical Specifications

Specifications listed in blue are unique to to Megatron Tank

-

- 24V Brushless DC motor equivalent to 2.5 HP AC motor

- Programmable gate speed controls, 16 selectable speeds – gate speed 11.5 to 20 seconds for opening and closing

- Automatic gate position reset system

- Gate sync feature provides automatic gate movement synchronization

- Modular system design for ease of service

- Switchable 115/230 voltage selection and solar option

- Adaptive DSP control for advanced brushless DC motion control

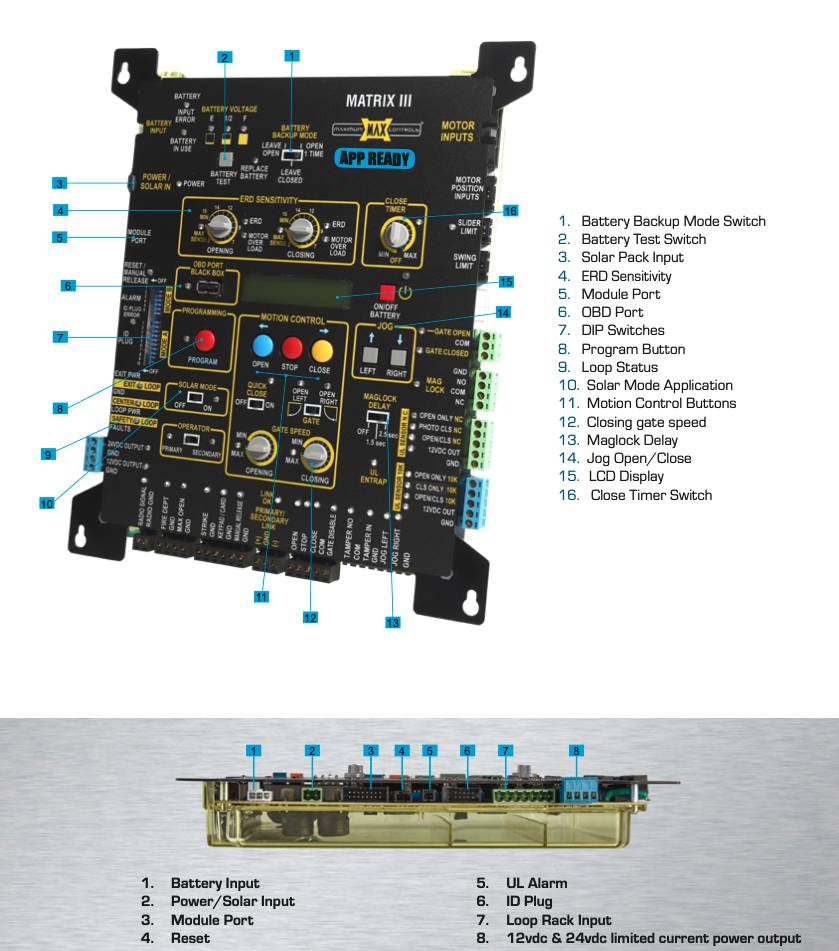

- Real time performance analyzer and event log (OBD PORT and Black Box)

- Low voltage wiring capabilities for remote power up 500 ft (no battery needed)

- ‘Solar Ready’ battery module with built-in advanced solar regulator – optional Max solar pack

- Intelligent power management system with energy saver mode

- Built-in 12vdc and 24vdc outputs power

- Gold contact input connections and automobile grade connectors

- Selectable open timer 0 to 60 seconds with ‘timer off’ option

- -4oF to 158oF (-20oC to +70oC) operational temperature range including battery performance without needing a heater

- Robust lightning protection up to 20KVolts and 10KAmps on all inputs and outputs (44 channels) including loop detector input connections

- Tunable 16-position safety obstruction sensor, auto adaptable to gate weight and size

- Dual motor overcurrent safety shut-off for additional protection

- Every operator includes a batterries providing 200 cycles (dependent on gate site) in case of power failure

- Three modes of selectable battery backup functions

- State machine design electronics with ultra-fast microprocessor

- On-board three button station

Megatron Tank Security Specifications

Specifications listed in blue are unique to to Megatron Tank

- High-traffic intuitive loop management system for better security

- Advanced security features with built-in audible and remote alarms

- Magnetic lock control relay outputs with selectable delay times

- Tamper alert relay output triggers “on” if gate is forced open

- Audible alarm if gate is tampered with or ERD is triggered for higher security

- Lockable cover with key lock release to prevent intruders and vandalism

- Gate disable feature, disables all inputs with exception of the fire department input for high security

- Built-in transaction buffer for higher security

- Gate status outputs for gate monitoring

- Direct motor control of jog OPEN/CLOSE for manually moving a gate in case of emergency

- Advanced anti-tailgate features to provide higher security

- No need for magnetic lock with the robust output shaft and clamp design of the Megatron Tank

Megatron Tank Safety Specifications

Specifications listed in blue are unique to to Megatron Tank

- Adaptive obstruction sensor for much better gate safety system. 16 selectable sensitivity settings

- UL 325/991 compliant Class I, II, III, and IV. CSA approved

- Pinch arm protection design

- Dynamic magnetic brake system stops the gate immediately to prevent damage to obstructions

- Built-in advanced entrapment protection and alarm output

- Built-in gate-in-motion alarm for industrial applications

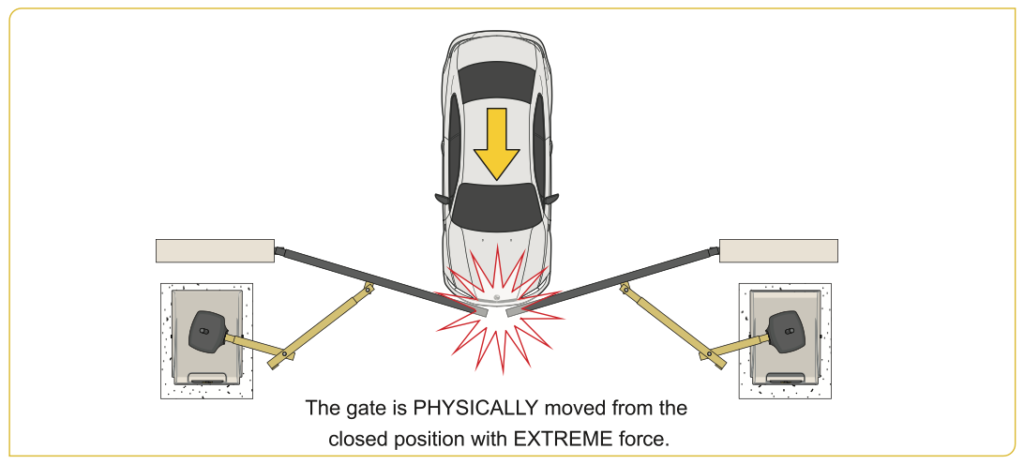

- VEHICLE HIT PROTECTION

- MECHANICAL RELEASE

- GEARBOX

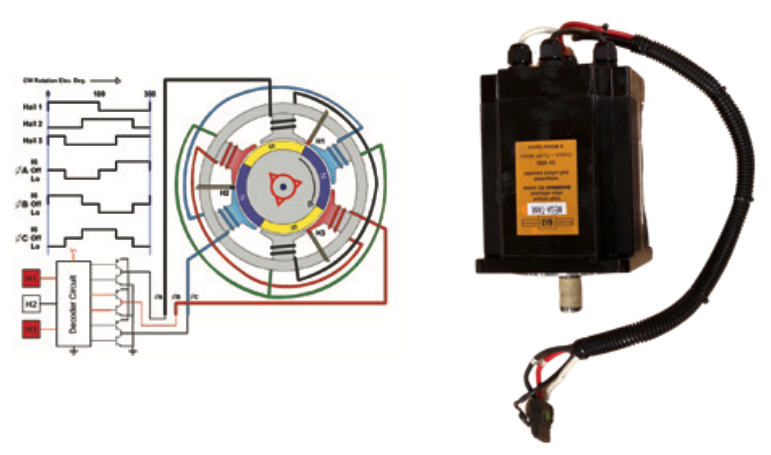

- BRUSHLESS DC MOTOR

- MOTOR CONTROL TECHNOLOGY

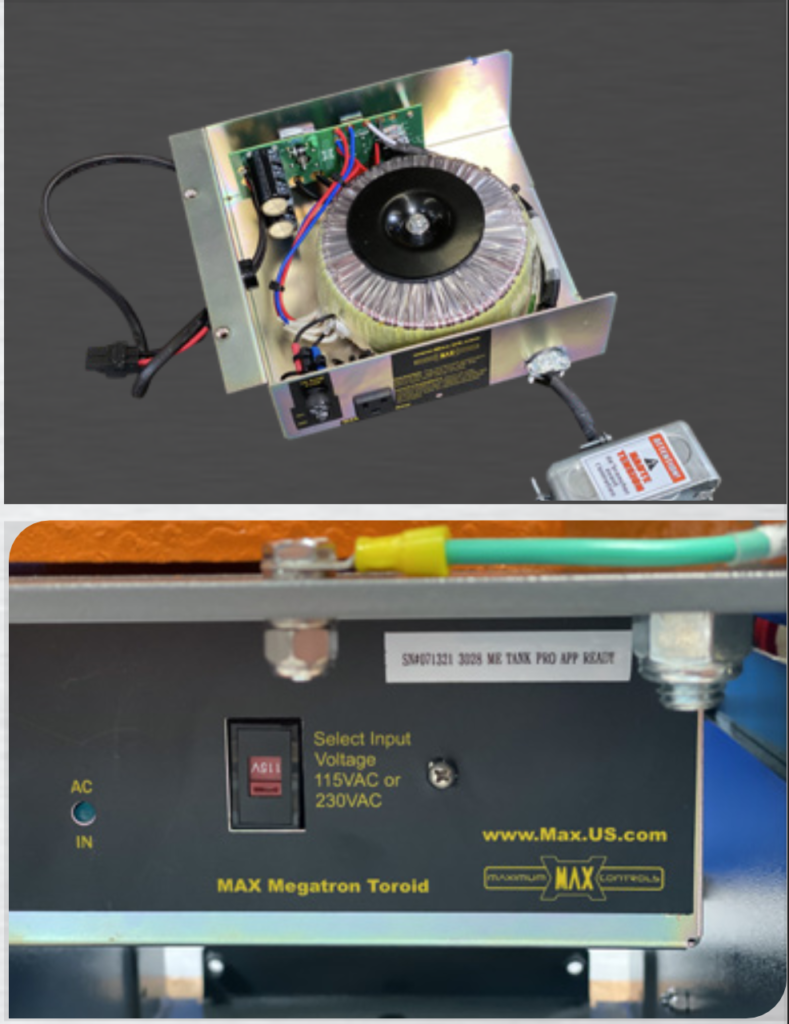

- POWER SUPPLY

Maximum Controls recognizes swing gates are more prone to vehicular collisions. For this reason the Megatron

Tank is outfitted with Maximum Controls’ clamping technology constructed with robust cast iron. The clamp grips onto a 31⁄4” diameter machined steel output shaft assuring maximum grip without the use of a shear pin/plate; allowing slippage in an event that the gate is struck while in motion by a vehicle. This prevents damage to the operator while preserving limit switch locations.

In case of a technical difficulty, the Megatron Tank has two manual release solutions. The first solution is the JOG OPEN & JOG CLOSE function. The JOG OPEN & JOG CLOSE function works by bypassing all Matrix-1 board inputs, serving as a electro-manual release solution even when the operator is not getting AC power but is still relying on battery backup. By installing an external “constant pressure switch” the JOG OPEN & JOG CLOSE feature can be accessed remotely.

The second solution is a mechanical manual release of the gate operator. Simply unlock the cap with a key, remove the cap and lift the red handle. The clamp is now loose and the gate can be pushed open manually. Manually releasing the operator in this manner will trigger the ‘gate-tamper’ relay. If the mechanical manual release is unauthorized, the gate tamper can trigger a security system. This is a high-security feature not found in any other gate operator.

The Megatron Tank implements a size 100, 900 to 1, direct drive dual gear reduction, high efficiency cast iron gearbox.

This gearbox is highly efficient, producing maximum torque, maintaining a low amperage draw by reducing resistance, providing super silent operation. The rugged cast iron housing, bronze gears, and double sealed heat-treated solid shafts have been designed by a team with over 40 years of experience in the gearbox industry.

High speed ball bearings and a synthetic oil bath keep the dual gear reduction operating flawlessly through extreme temperature ranges without need for belts, chains, or pulleys which are subject to wear, raising maintenance issues.

We invite you to compare our Maximum Controls gearboxes to any of those used by other manufacturers.

The brushless DC motor in the Megatron Tank uses “Hall Effect” magnetic sensing to identify over five thousand precise rotational positions during 90 degrees of gate movement. That’s over 50 samples per degree of gate travel. Using this positional feedback, intelligent ramp-up and ramp-down of the gate speed is employed to minimize stress on all mechanical components.

The Hall Effect sensors know the position of the gate at any given moment thus can synchronize the gates to open and close at the same speed. We combine this technology with a dynamic magnetic brake system which stops the gate instantly when colliding with an obstacle.

Our brushless DC motors can withstand and operate in extreme high temperatures up to 158oF (+70oC); this surpasses any other motor technology we know of in the market today.

The Max brushless DC motor’s torque is equivalent to a 2.5 HP AC output torque motor and can operate approximately 35,000 hours, (about 6 million cycles). Therefore, the motor will last for decades to come.

Maximum Controls’ brushless dc motor control enables precision movement that traditional brushed motors can not replicate. Advantages of this level of control is the ability to stop instantly – which is critical in emergency situations when a safety edge is struck, stopping on a dime to reduce risk of injury or damage to equipment is imperative.

The Megatron Tank’s power supply utilizes a 30 Amp torroid and power management board. The power supply is efficiently designed with ample headroom and is not overstressed under any extreme load or temperature conditions. The power supply input accepts 115V or 230V AC via selection switch. During gate operation the battery is not utilized while AC is present, preserving the life of the battery.

Input AC Power/Amps –

Switchable: 115VAC / 6 Amp, Single Phase or 230AVC / 2 Amp, Single Phase

- BLACK BOX & LOOP MANAGEMENT

- ADVANCED SECURITY

- LIGHTNING PROTECTION

- CONTROL FEATURES & CONNECTIONS

- WARRANTY

One of the primary goals of the Megatron Tank is to provide the most secure, easiest to maintain gate operator with higher gate speed motion and advanced loop management.

The Megatron Tank uses non-volatile memory to continuously log performance characteristics and input/output events. A service technician can access this data via USB port to download the event history, quickly diagnosing complex or intermittent problems that traditionally have been very difficult to isolate and repair. By plugging a USB thumb drive into the USB port, all the Megatron’s diagnostic history will download, working as a “Black Box” to diagnose what occured. The Megatron’s event history is stored as a .TXT document which can be emailed to the factory if necessary, for on-site diagnosis. The .TXT file is a log of the most recent 1000 events reported by each module to the central logger.

The Megatron Tank’s standard intuitive loop management system, when enabled, will discourage tailgating, increasing security for residential and High-traffic installations. When the anti-tailgate switch is activated, any car tailgating a legitimate access will be forced to stop by a rapidly closing gate, forcing the tailgater to back up and thereby triggering the gate to close and deny unauthorized access.

When disabled, loop management will allow multi- access, with the gate opening on each successive trigger in the traditional loop management manner.

Anti-Vandalism/Burglar Alarm

As a security device, the Megatron Tank supplies a gate tamper relay output that triggers whenever a gate has encountered an unauthorized movement. This can be configured to activate an alarm system or camera. The Megatron Tank also has a gate disable feature which can disable operator open commands during a vacation or overnight for commercial applications.

The Megatron Tank offers the most robust lightning protection available in the industry. The Megatron Tank protects all peripheral inputs, loop inputs, power inputs, relay outputs, and all communication lines (over 44 channels of protection) in 1/1,000,000,000 of a second. With special emphasis on power supply protection, the Megatron Tank is guaranteed to withstand any lighting hit more than 50 feet away. Truly protected like no other operator in the world. The operator must have a propertly installed ground rod for the lighting protection to work propertly.

Section I Coverage

- 2 years on all components

- 1 year on batteries

Section II Not Covered

- Damages due to flooding

- Damages due to fire

- Damages due to negligence i.e. leaving the cover off in the rain, improper wiring of AC or peripheral systems

- Damages due to product misuse i.e. gate and operator combination mismatch

- Damages due to vandalism

Section III RMA Shipping Policy

- Maximum Controls LLC will pay for return shipping via standard ground UPS or USPS FOB CA on all RMA’s within one year of Distributor’s purchase

- Any form of “Expedited Shipping” on any RMA will be paid by Distributor

Section IV Product Returns

- Products must be in original, resalable condition with all warranty information, manuals, and original packaging.

- A re-stock fee of 10% will be charged on all returned products.

- All returned products must reference a Maximum Controls PRA number or it will be refused.

- Maximum Controls is not responsible for freight charges associated with returned merchandise.